Willing® ST3 - Structural PVB interlayer

Current architectural design trends are driving the increased use of glass in building design. As a result, architects and designers need glazing products that can help them bring more natural lighter into a building without sacrificing structural integrity.

standard WILLING® films.This makes it an excellent choice for special applications such as glass floors and stairs, curtain walls and parapet glazing. In architectural glazing, long-term adhesion is an assurance of the high quality and long service life of the laminated glass

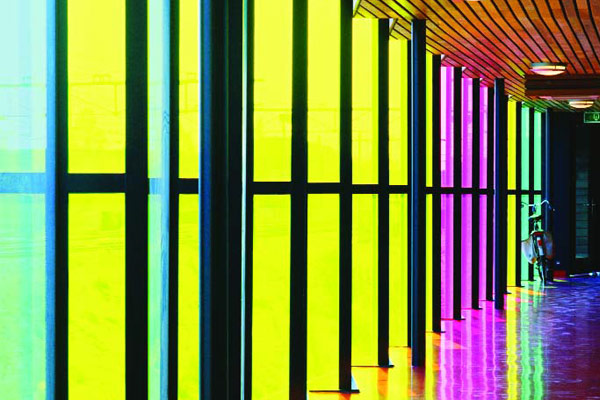

Laminated glass made with Willing® structural PVB interlayer helps create solutions for a variety of glazing performance needs and aesthetic design target. Among the many demands placed on construction projects, two basic requirements remain constant. The building and all its components must be structurally sound and must keep weather elements from entering the building. A breach in the building envelope can result in a range of undesirable and often dangerous outcomes – including internal pressure, exposure of occupants to wind and rain, damage to building contents and disruption of business. Laminated glass with Willing® structural PVB interlayer can meet building standards in applications such as insulated glass units, overhead glazing and glass floors. In an insulated glass unit, the lites share the load equally so long as the lites are the same type (annealed, heat-strengthened or fully tempered) and thickness, and are relatively thin. Otherwise, load sharing will be unequal and must be calculated to determine the strength of the unit. Insulating units can use laminated lites in one or both glass positions. When laminated glass is used as only one lite of an insulating system, in most applications the laminate should be placed toward the building interior. For optimum protection of occupants and passersby, the use of double laminated units should be considered.

Overhead glazing. As defined by the three model building codes, overhead glazing is glass that is positioned over space that may be occupied by humans. In these applications, the codes prescribe laminated glass for either a single lite or the lower lite in an insulating glass unit – although other products are allowed provided post-breakage controls are in place, such as mesh under tempered glass. Overhead glazing should not be exposed to the weight of a person and should be designed to discourage people from walking on glass surfaces.

Laminated glass floors are popular currently, and calculations for floor loads can be found in the model building codes. In designing glass floors (walking surface of floors, landings, stairwells and similar locations) for human and other loads, it is generally recommended that architects and designers use the following criteria: 1.Laminated glass should have a minimum of three plies and should be capable of supporting the total design load with any one ply broken.2.Surface damage caused by people or objects placed on glass can significantly reduce the strength of glass (subjecting it to breakage under subsequent loads) and should therefore be considered in the design. Glass floors may be subject to conditions that make them slippery or targets of high-pressure or -impact loads. The surface of the glass and the application areas should be given special consideration during design.

Willing® structural PVB interlayer can be apply for use in laminated glass of stair railings and balconies in stadium

Willing®ST3 is a clear, strong, rigid film produced from special plasticized polyvinyl butyral. It is designed specifically as an interlayer for applications where increased interlayer rigidity and high glass adhesion are required relative to standard glazing interlayers. Willing®ST3 provides superior structural capacity versus standard PVB interlayers and is designed with ease of processing in production. Laminated glass as a building material for external and internal facades that have experienced a striking upsurge in recent years widely. Tempered glass produced to meet the human impact requirements has been used for years. The awareness and risk of sudden rupture, failure and fall-out caused by nickel sulfide inclusions, processing or installation has been heightened by coverage in glazing industry trade journals. Although tempered glass has been traditionally used for its load strength and safe break characteristic, the fragmentation upon breakage that showers from tall buildings can become dangerous and affect pedestrian well being, cause vehicular damage and even close down passageways and roadways for long duration. This can affect retail, hospitality and in some cases emergency services. Willing®ST3 combines the benefits of a rigid interlayer with the features of glass containment, UV screening, stability, clarity and noise abatement.similar to the formulation used in aircraft windscreens, and built upon the performance specific attributes of cyclone/hurricane and typhoon resistant PVB interlayers, Willing®ST3 interlayer is unlike standard PVB interlayer in that it is significantly more rigid. Furthermore, Willing®ST3 interlayer in a properly designed system, is capable of keeping glass intact at hot and cold weather or high and low temperatures, even after impact and under load. Willing®ST3 is unique in that it combines the meaningful performance and processing characteristics while allowing for balanced engineering practices which can lead to more efficient whole building design.