PVB interlayer composition

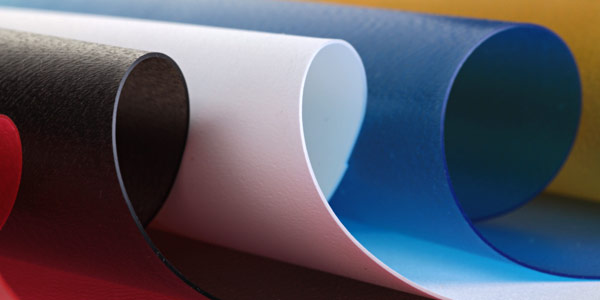

PVB interlayers full name called Polyvinyl Butyral interlayer, ahereinafter to be referred as PVB film, it consists of 75% PVB resin, 25% plasticizer and a small amount of other substances as additives manufactured, these substances owns strong adhesion control agent, ultraviolet inhibitor, and with different pigment of colors, collectively referred to as additives. PVB film is a translucent film, no impurities, flat surface with little roughness and excellent flexibility, it’s good adhesion with glass, laminated glass with Willing® PVB film which display ultra transparent, with good tolerance of high and low temperature, thermal shock, humidity and high mechanical strength characteristics, so it is the best adhesive for sandwich glasses and laminated glass processing in the world. while it widely be used for architectural glass such as building facades, overhead glazing, windows, doors, bulletproof glass, balustrades, retail shelving, skylights, flooring, furniture, partitions and a variety of other building safety glasses, another big application for automotive glass and transports glasses like windshields, sidelite, body glass, backlite, roof panel also has a wide field of applications.